In a specialized market segment, Von Roll Composites manufacture high precision plastic parts. They respond to the technical pursuits of competitors with even more precision. A high-precision sander from Kündig is used for this, which allows only a few hundredths of a millimetre tolerance.

In a specialized market segment, Von Roll Composites manufacture high precision plastic parts. They respond to the technical pursuits of competitors with even more precision. A high-precision sander from Kündig is used for this, which allows only a few hundredths of a millimetre tolerance.

Accuracy seems to run in the blood of Hans Haas, Production Manager for composites at Von Roll Swiss AG in Breitenbach: “We are specialists in the treatment of plastic parts with a tolerance that is otherwise only known in precision mechanics.” These highly accurate parts are needed mainly because of their insulating qualities – for wind power plants, medical equipment, oil platforms or submarine engines. ”We make use of a whole range of materials with tailor-made qualities which allow us to meet requirements and craft them precisely”, Haas explains and cites glass or kevlar reinforced plastics. The market they supply is relatively small due to its specialist nature, but deeply interesting: “This makes competitors appear. But it’s too simple to say, I just start to produce these parts. One needs know-how and experience to keep the necessary tolerances.” To put it boldly: The high accuracy with which today’s iPhone is made, would not be enough for these very special parts. Von Roll still has the advantage, smiles Haas, „But of course the competitors are gaining on us. We must not rest on our laurels.“ Obviously they didn’t, instead Von Roll invested in even more precise production equipment like a five axis CNC and a high precision sander from Kündig.

Tolerances in the range of hundredths

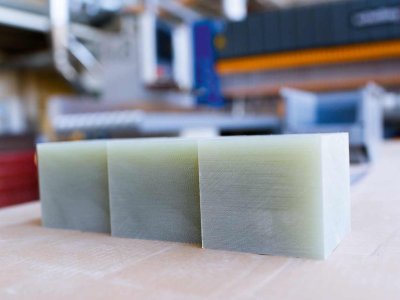

Base material composite boards of 1070 x 2700mm are used. According to Haas, the key to even more precision lies in these boards: “Due to production factors the boards still have a too big tolerance for us which we have to equalize before treatment. Don’t get me wrong – these boards are calibrated exactly, but not with the precision we need for our special purposes.” The less thickness tolerances there are, the more exact the CNC-treatment will be, he resumes: “The logical conclusion was that we have to calibrate them with even lower tolerances, to get a better component precision.”

In terms of numbers, this means that only 0,3mm thin boards are allowed to have a tolerance in thickness of only a few hundredths of a millimetre. Particularly when measured over the entire dimension of 1070 x 2700mm. “Our old sander wasn’t built for this. Therefore we asked Kündig in Switzerland if they can do better.” They can.

Systems for particular solutions

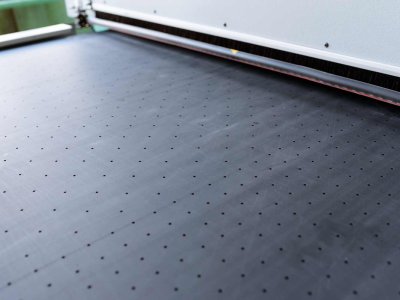

”Such demands are not uncommon with our customers from aviation and automotive industries”, comments Stephan Kündig, Technical Director of Kündig AG. „Our Technic series was created especially to make tailor-made solutions possible.” For the high-precision sander at Von Roll, Kündig was able to draw mostly on proven constructions: “We used two of our high-precision sanding heads here. They allow us a highly accurate adjustment of thickness over the entire working width. A modified feed guarantees that tolerances can also be kept in the longitudinal direction.” Other precision advantages – like the fine-tuning of grit-sizes – are already standard on every Kündig sander, Stephan Kündig points out.

Tolerances of ± 0,015 mm

Under optimal conditions, the Kündig Technic Precision-2 1350-RRrz ensures a distinct lower deviation of default tolerances, Haas is enthusiastic: “Our measurements resulted in constant ± 0,015 mm on all measuring points over the entire Board.” That is not the norm, he notes: “With this range of tolerances regular machine-maintenance is important, otherwise precision would drop. One must factor this like costs for tool sharpening.” The constant performance of this Kündig Precision is extremely satisfying, says Haas: “We can now keep our default tolerance of ± 0,03 mm with ease.” It was a worthwhile investment, Haas confirms: “We obtained a better component precision and retained our regular customers. And with the once again increased precision it was even possible to attract new customers.