Botop

All surface sanding tasks in one pass

Our Botop series of wide belt sanders are built for double-sided sanding in just one pass. They combine high performance, efficiency and excellent sanding quality on the workpiece's bottom and top side. Typical users of this machine series are panel manufacturers ▶ Video, veneer processing specialists ▶ Video or stair construction companies. However, the technology is also suitable for many other materials and applications. ▶ Video

Time saving and compact

A single employee is enough for feeding the sander. Integrating the system into automated production lines works flawlessly. Thanks to double-sided processing, most sanding tasks can be done in just one pass, which greatly improves efficiency and saves a lot of time. Another advantage of our Botop series of machines is the compact space requirements, which further facilitates integration into industrial production lines. All of the technology necessary is incorporated within the machine body.

Bottom Sanding Solutions

In more than 95% of cases our customers rely on our Top and Bottom-Top sanders. But there are situations where a dedicated bottom-only sanding solution will make sense by elegantly solving a problem well known to production plant planners: In a production line, processing a work piece from below, if possible, is usually much easier to do than having to flip it upside down. In such situations, a bottom sander makes all the difference and usually saves a lot of effort as well as money. And since these are basically the same technology as our regular top sanding machines, they can be equipped with almost all of the same sanding technology.

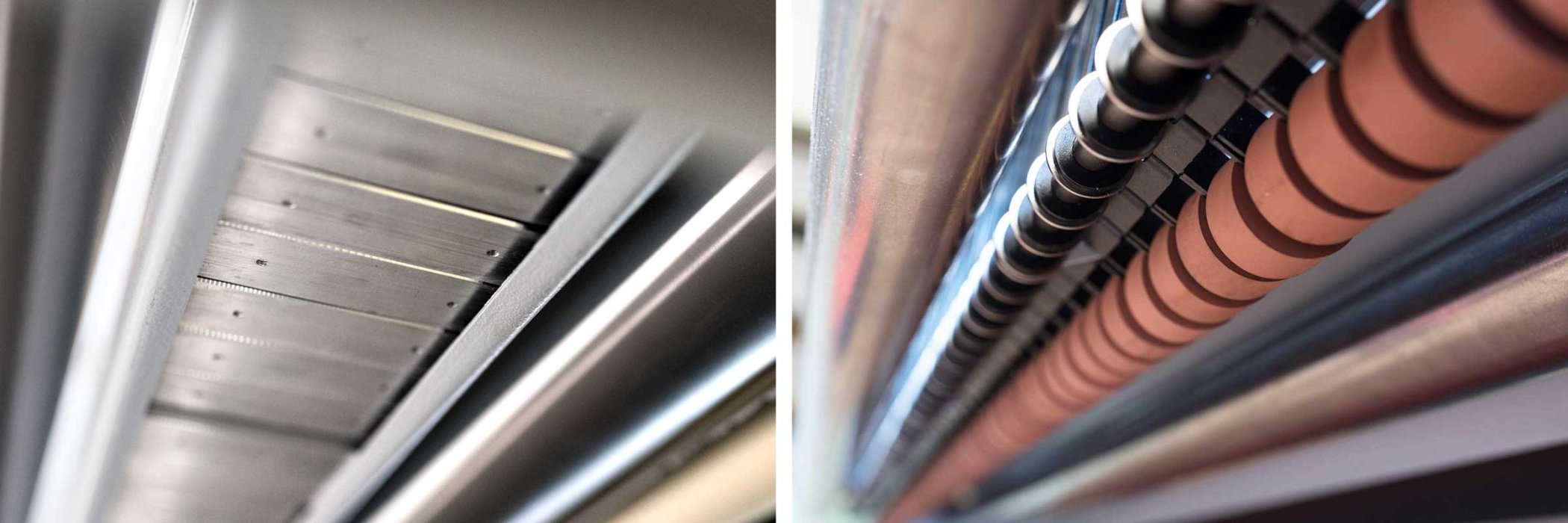

Sanding Pads

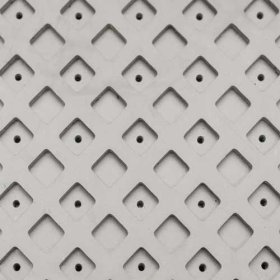

Pneumatic Pad

Well proven sanding pad technology, especially for solid timber processing. A continuous air cell provides even pressure on the workpiece.

Segmented Pad

The segmented pad is divided in segments either 35 or 22 mm wide. These segments are computer controlled and preferences can easily and thoroughly be adjusted by the operator. The electronically controlled, segmented pad is especially useful for taking care of those delicate workpiece edges on lacquered or veneered parts.

Pad Options

Segments and therefore the sensing rollers at the machine entry are available in 35 or 22mm width. Depending on the material that needs to be sanded, a variety of sanding shoe hardnesses are available. Two different hardness shoes are included from the factory.

Units

Our Botop series of wide belt sanders offers the convenience of double-sided processing in just one pass and combines it with options of parallel sanding or the Kündig exclusive oblique sanding technology. This technology has a variety of advantages: Vanishing of sanding traces on the work piece, longer belt life span, less fiber-raising and therefore much finer surfaces and less lacquer consumption.

Top and bottom sanding units are available as planers, brush units, calibration rollers and sanding pads, either pneumatic or segmented and electronically controlled. They offer, as usual, a very stable support, high precision build and above average life span. For high output applications and the heat build-up that comes with them, there are different belt lengths of 1900, 2000, 2620 and 3250 mm available.

| Calibration Roller R | Calibration Roller G | Calibration Roller Rd | Sanding Pad P/E | Pneumatic Pad Pd | Electronic Pad Ed |

|---|---|---|---|---|---|

|

|

|

|

|

|

| Calibration Roller | Large Calibration Roller | Calibration Roller oblique | Sanding Pad electronic or pneumatic | Sanding Pad oblique pneumatic | Electronically controlled segmented Pad oblique |

Working Widths

| 650 mm | 1100mm | 1350mm | 1600mm | 1900mm | 2200mm | Different Working Widths on Request |

Options

|

Enormatic The machine measures workpiece thickness and starts the sanding process automatically. |

|

Touch Screen The operator can choose between automated and customisable quick start programmes and manual operation adjusting all the relevant parameters. |

|

Conveyor Belts |

|

Lacquer Package |

| See more options |