Precision

Despite the Kündig standard machine series being already very precise, the Technic Precision series goes even a step further and offers adjustment increments of just 1/100mm.

But even with Kündig standard production machines very tight tolerance requirements can be met thanks to a number of factors:

- Sanding units can be adjusted to specifically compensate for varying sanding grain height of different sanding belts

- All components are produced to the highest precision standards - from spindle gears, for height adjustments, to the sanding belt assembly

- A sophisticated software monitors and corrects all relevant parameters

- There are dedicated precision sanding units that implement a variety of specialized technologies.

Sanding with 1/100mm tolerances

Ordinary sanders allow for adjustments in increments of 1/10th of a millimetre. Our Technic Precision series goes one step further. It allows adjustment using 1/100th millimetre increments.

For demanding Calibration Applications

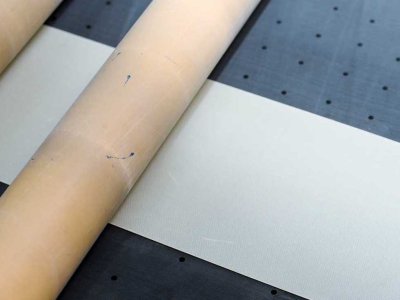

Processing modern high-end materials to tolerances that are usually only known in precision mechanics is often impossible using traditional methods due to the properties that some of theses materials have. High precision sanding can be the solution that helps meet these high requirements in materials like carbon fiber. For example: Carbon fiber brake discs used in aircraft and automotive industry are processed with Kündig sanders. But the same requirements are often found in the wood processing industry too. Veneer sheets have to be calibrated so that close tolerances on the large dimensions of cross laminated beams made of veneers can be ensured. To list some examples:

- Calibration of laminate materials HPL/CPL (tolerances up to ± 0.005 mm)

- Sanding of honeycomb sandwich panels (tolerances up to ± 0.01 mm)

- Sanding of veneer, also top/bottom (tolerances up to ± 0.01 mm)

- Many other materials such as plastics and composites, rubber belt, cork from a spindle

- Our CNC sanding technology for precise and repeatable contouring of parts

- Working widths and belt lengths depend on the application type